In recent years, there’s no doubt that we’ve seen the rise of artificial intelligence in a number of industries. Coffee roasting is no exception, and with the growing prevalence of automation in the sector over the past couple of decades, AI is an obvious next step.

There are several advantages that using AI can bring during roasting, which range from improving efficiency and minimising workload to greater precision and lower costs.

To learn more about AI in coffee roasting, I spoke to three coffee professionals who work with it on a regular basis. Read on to find out what they told me, and why AI could be the future of roasting.

You might also like our guide to what a production roaster does.

How is AI becoming more prominent in coffee roasting?

Along with many other industries, coffee roasting has made huge strides in recent years as far as automation is concerned. Today, commercial coffee roasting no longer requires anywhere near the same workload as it did even just a couple of decades go.

Veronika Galova is the Head of Marketing at ROEST, a professional sample roaster manufacturer.

She says: “AI is becoming a popular technology in various industries, not just coffee roasting. This is because it can ultimately deliver better results with higher efficiency.

“In the coffee industry, what we value the most is greater consistency and improved quality of the final product,” she adds. “From a business perspective, AI can reduce workload and therefore cut costs.”

While the initial investment for the latest AI-powered roasting technology might be high, this can be offset in the medium and long term in a number of ways. These include increased precision, no human error, a lower workload, and less wastage.

“It can also make it easier to find the right human resource from a business owner’s perspective,” Veronika adds. “This is because AI-powered coffee roasters don’t require as much skill to operate in the first place.

“As a result, roasting teams can be leaner and more agile, as well as putting more of a focus on cupping and overall coffee quality.”

Ultimately, AI in coffee could remove the skill barriers preventing aspiring roasters from entering this segment of the industry.

How is AI actually used to roast coffee?

Hidenori Izaki is the 2014 World Barista Champion and is a coffee consultant. He says that working with AI allows him to work more effectively and efficiently than he has in the past.

“I work as a coffee consultant, and I have clients which include coffee and food & beverage chains,” he says. “I mainly cover product development and quality control with research & development departments.

“This means that clients send green coffee to us, and we use ROEST to make sure they roast [as the client wants them], or to develop the right roast profiles [for these coffees].”

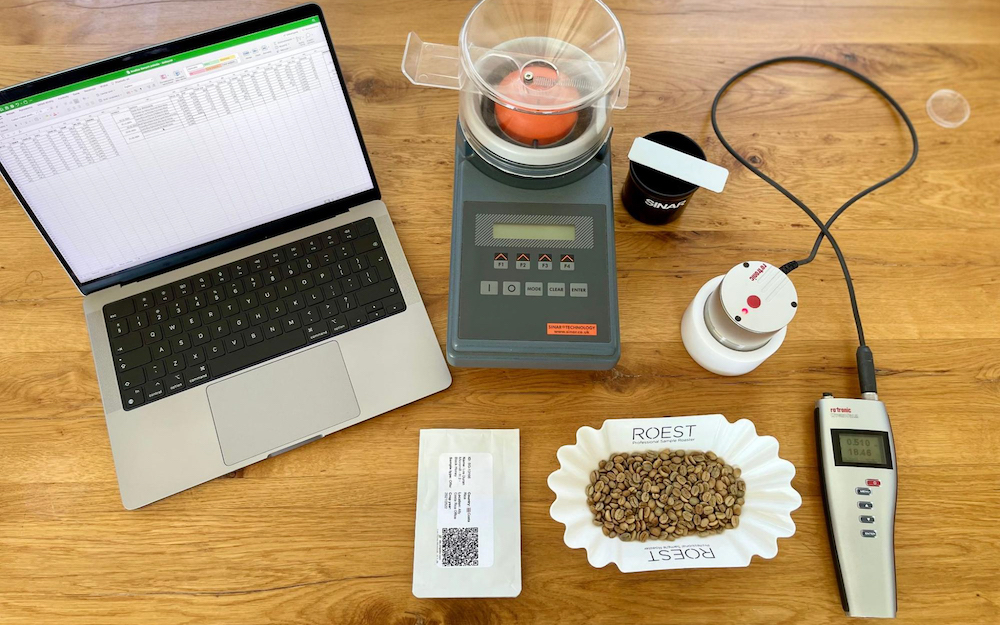

Manufactured in Norway, ROEST machines are high-quality sample roasters. Among the machine’s flagship features is its AI-powered automatic first crack detection function. It also records a range of key data points throughout the roast.

“Since my client is a fairly big company, I have to provide them with data, and analyse it to help convince their team,” Hidenori continues. “ROEST is really helpful for this, as it provides so much data throughout the process.”

Hidenori owns a ROEST L100, which has a range of temperature sensors (for the air, the beans, the exhaust, and the drum) to provide users with even more data throughout the roast.

Historically, professional coffee roasters had to use their senses to guide a coffee through the roast, relying on intuition and experience. Over the last couple of decades, data logging software has become commonplace.

Leveraging AI to utilise this data, however, is a more recent development. AI technology can analyse the progress of a single bean throughout the roast, and automatically adjust temperature and airflow when the data indicates that it’s time to do so.

Hidenori says that ROEST’s automatic first crack detection technology was one of the reasons he invested in it.

“One of the reasons I decided to get a ROEST machine was its automatic first crack detection function,” he says. “This is because first crack decides not only quality, but also consistency.

“We know consistency is important, and so, using a high-quality microphone to detect first crack is obviously better than human hearing. This means my roasting is more consistent than ever.”

He adds: “With each batch, I know how ‘strong’ the crack is, and this data is really useful for pursuing consistency.”

As much as charge temperature, turning point, and roast time are all key to a roast profile, first crack timing is essential, as the difference between under and over-roasting can be a matter of seconds.

Using a microphone to record first crack makes identifying and predicting it (over multiple batches) even more precise. This is especially important when we consider that different coffees crack at different volumes. Coffee roasters operate in noisy industrial environments, which can make it difficult to tell when their beans are approaching the end of their roast time.

Veronika explains that ROEST has developed a system that allows the AI controller to listen out for first crack.

By recording first crack, the user is able to adjust the roast profile based on the differing amount of “pops” – something the human ear wouldn’t otherwise be able to discern.

Veronika adds that the company is also working on a 2kg production roaster with the same technology.

“In the production area for major roasteries, it can be nearly impossible to make out these cracks without the use of microphones and AI,” she explains.

What are the benefits of using AI in coffee roasting?

Reports indicate that French food manufacturing group Danone saw a 20% decrease in forecasting errors, a 30% decrease in sales loss, and a 50% reduction in the demand planners’ workload after scaling up AI in its operations.

The benefits can generally be split into two key categories: efficiency and precision.

But how, specifically, are these benefits realised in the coffee roastery?

Improving workload for coffee roasters

One of the main benefits of using AI in roasting is improving the workload for staff at a roastery.

Espen Stokkan-Smith is the Lab Manager at Nordic Approach, a green coffee importer. He says: “We use the ROEST for all our sample production – both for internal cuppings and samples for customers.

“We average over 160 roasts per week over the year, with our busiest times experiencing that amount daily.”

At this kind of scale, the logistics involved with individually managing each of these roasts are well past unmanageable. AI saves time and stress for everyone involved, automating much of the arduous organisation that would otherwise be involved.

Franciska Apró is a quality control coordinator for SUCAFINA. She adds that it’s not just the act of roasting that AI helps with – it’s also profiling.

“We use our ROEST for all incoming offers, as well as preshipment and arrival samples,” she says. “Since we receive thousands of samples every year, we don’t have time to develop profiles for every single coffee.

“We work with a handful of different profiles, and we decide which one is most suitable based on moisture, density, and processing method,” she adds.

Ultimately, adjusting and adapting based on these characteristics is a much quicker process when AI is involved.

Consistency & quality

While workload is one immediate benefit for the teams that use AI-powered coffee roasters, another key priority is consistency. To put it simply, using AI in the process of roasting eliminates human error.

However, where roasting coffee samples is concerned, human error can compromise the flavour of a sample. In turn, this could potentially influence a major purchase for an importer or a large commercial roaster.

“During busy times, AI allows for greater and safer multitasking,” Espen says. “It gives you the security of being able to monitor roast data at a glance, rather than being stuck at the roaster.

“This [manages consistency], while freeing up time for other tasks such as packing and sending out coffees, cuppings, answering emails, and a hundred other things.”

Another challenge when roasting coffee is adapting the roast profile to the surrounding environment. The elements can play havoc with consistency, and roasters regularly adjust their set profiles to account for seasonal shifts and weather fronts.

With AI, roasters can automatically account for these changes, and adjust the roast accordingly in real time – far quicker than a human ever could.

Helping the rest of the supply chain

“If we want to sell the amazing coffees we source, we have to send samples to our clients,” Franciska says. “Sometimes even roasters who own a sample roaster order roasted samples from us, because they like our roasting style and it saves time for them.

“This means we’re usually dealing with a huge number of sample requests, and flexibility comes in handy. With the ROEST, we can roast batches up to 120g that can be easily split between three clients.”

Ultimately, when sample roasting can occur more quickly and more accurately, decisions can be made on a much faster basis. This kind of agility has effects which are felt further along the supply chain. For the roaster, it means being able to commit to buying a certain volume of coffee much more quickly, whereas for the producer, it means their coffee is shown in its best possible light more often.

Conversely, poorly roasted samples have a significant knock-on effect further down the coffee supply chain. Ultimately, any way of improving the consistency and quality of roasting serves as a huge bonus to everyone involved.

Ultimately, the presence of AI in coffee roasting is growing. Around the world, more and more roasters and their suppliers are leveraging this technology to improve consistency and automate work where they can.

Whether it’s used to anticipate ideal stock levels, predict first crack, or automatically guide a roast profile, AI clearly has benefits to offer for coffee roasters. How quickly it will be taken up across the industry remains to be seen, but it is a clear example of how today’s coffee industry is evolving.

Enjoyed this? Then try our article on what a Head of Coffee does day-to-day.

Perfect Daily Grind

Photo credits: ROEST, Bagus Heru Setiawan, Krzysztof Barabosz

Please note: ROEST is a sponsor of Perfect Daily Grind.

Want to read more articles like this? Sign up for our newsletter!

The post Exploring AI in coffee roasting appeared first on Perfect Daily Grind.

By: Josef MottTitle: Exploring AI in coffee roasting

Sourced From: perfectdailygrind.com/2022/03/exploring-ai-in-coffee-roasting/

Published Date: Wed, 30 Mar 2022 05:37:00 +0000